Lime Wall Plaster - Color Skim 102-5 Gray

Lime Wall Plaster - Color Skim 102-5 Gray

Couldn't load pickup availability

Product Instructions & Further Information

Product Instructions & Further Information

If you would like product instructions for a particular product, please don't hesitate to contact us and we'll be happy to email you the product installation documents. Installation information is sent with products as well on an attached document.

Need Product Recommendations?

Need Product Recommendations?

If you could use a recommendation for materials to sample or use on your project, please don't hesitate to contact us and we'll do our best to help guide you in the right direction!

A Mineral Alternative to Painting

Replace paint with this non-sanded smooth lime plaster. Designed as a skim-coat color finish, it creates a stunning decorative mineral surface on interior walls. This finish can be applied over both primed drywall and plaster walls.

Coverage and Surfaces:

Coverage: 50-75 SF per-gallon

Application: Venetian Plaster Trowel

Surfaces: Interior Walls

Primer: Pro Mason Plaster Primer-Smooth (on drywall & non mineral surfaces)

Visual Depth & Movement

This plaster is colored with only mineral pigments to create depth and color variation. The pigments highlight the visual movement created by the application strokes and the minerals within the finish.

Composition & Surface Compatibility

Color Skim Wall Plaster creates a breathable and beautifully smooth finish with visual depth and is applied as a paper-thin skim coating. The finish and composition is similar to Veneziano and venetian plaster with no sand within the lime and fine crushed marble plaster. It can be applied to most smooth interior wall surfaces such as drywall after being primed as well as plaster walls as a final color finish.

Customizable Sheen: Matte or Burnished

This finish can be burnished to increase sheen or be applied as a matte finish with no burnishing action, which is an easier process for DIY projects. Rewetting the surface to work to a smoother finish prior to initial setting is possible to create a highly refined finish.

Application Thickness & Preparation

Color Skim Wall Plaster is intended as a final color finish to be applied to smooth surfaces that have been primed with Pro Mason Plaster Primer Smooth or to a dampened mineral plaster substrate. should not be applied thicker than 1/16” in a single application and should not be used to build surfaces.

Easy Mixing & Extended Working Time

Add water only and mix to a workable paste. Mixing with a mechanical drill mixer designed for paint or plaster is advisable to create a smooth, lump-free mixture. This hydraulic lime plaster has a slow set time relative to gypsum plaster skim coat finishes. This can be helpful for those who are new to plaster work and reduces urgency to work quickly. This plaster is formulated to retain water during drying and does not require misting or damp curing in normal conditions.

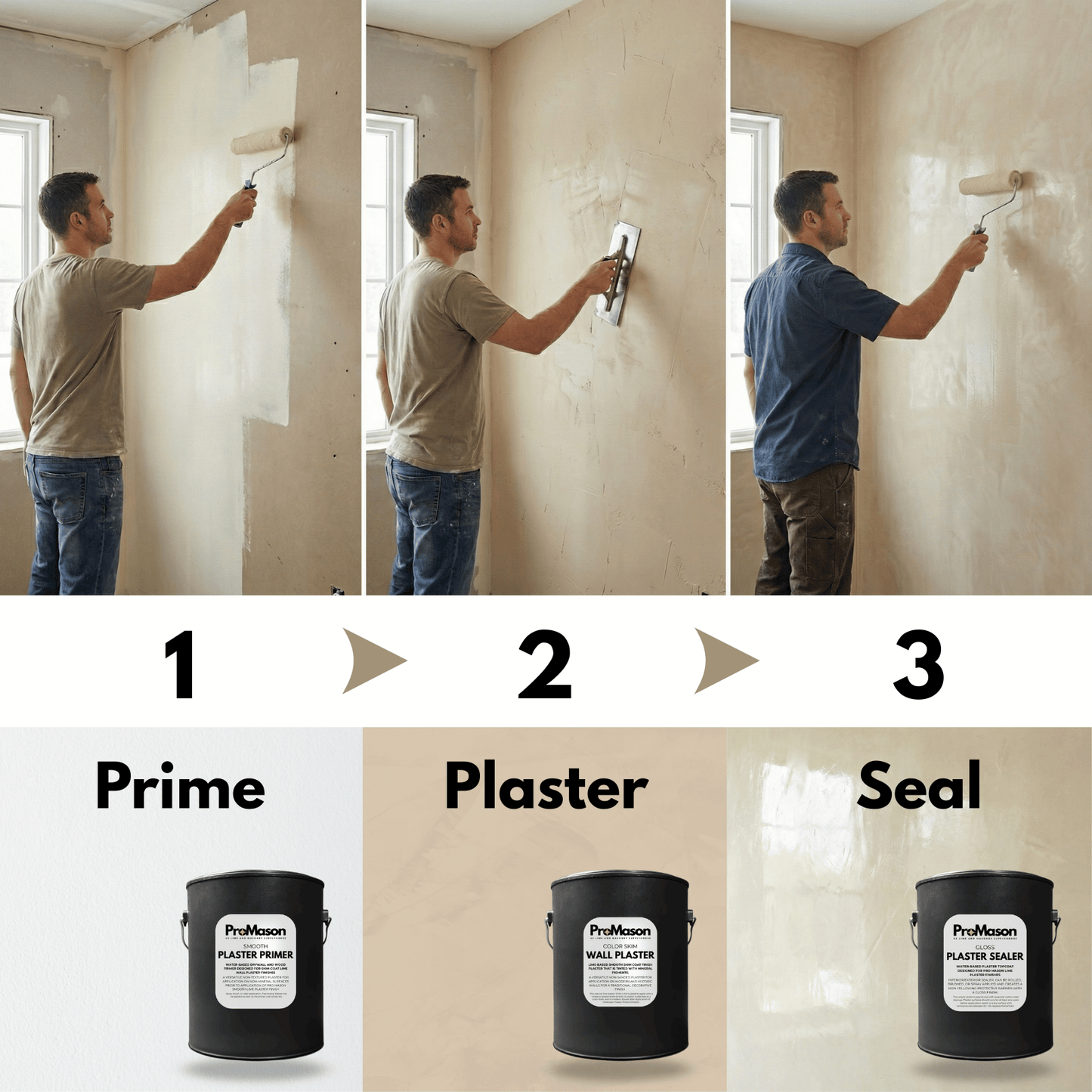

Application Instructions: Pro Mason Color Skim Wall Plaster on Drywall

1. Surface Preparation Prepare the drywall to a smooth surface (Level 4 finish or higher is ideal). Fill holes and complete all mudding and taping before proceeding.

2. Priming Apply one even coat of Pro Mason Plaster Primer Smooth using a paint roller. Allow to dry fully.

3. First Coat Apply the first coat of plaster at 1/16” or thinner. Do not attempt to achieve full coverage or build up the surface; this is a decorative color finish and will crack if applied too thickly. It is better to apply multiple thin layers than one thick layer.

4. Smoothing Once the first coat is dry, lightly sand with fine sandpaper or knock down high points with a plaster knife to ensure smoothness.

5. Second Coat Apply the second coat. If conditions are warm, you may mist the surface immediately before application to extend working time. Note: Do not mist finished work unless you plan to re-trowel that area.

6. Third Coat & Burnishing If needed, apply a third coat once the second is dry. After the final coat is fully dry, you may burnish the surface to increase sheen and depth.

7. Curing & Sealing

-

Water-Based Sealers: Allow the plaster to cure for 2–4 weeks before applying. Use water-based sealers only.

-

Wax, Soap, or Oil Finishes: Allow a minimum of 48 hours (1 week recommended) before applying.

Temperature: Air and surface temperatures must be maintained between 55°F (13°C) and 85°F (29°C).

Humidity: Ideal relative humidity (RH) is 50%–75%.

Share

Let customers speak for us

from 76 reviewsI bought from them a few different times, the product comes quick, high quality, definitely recommend

I bought 5 gallons of PHL 3.5 Lime Mortar to repair the old stone walls of my basement. I am about halfway done the job. I will soon order another 5 gallons because this product is perfect for the job.

Great product. My order was filled quickly. We had some mortor joints we repaired and the color samples were ordered were a great match.

Great products and fast shipping, provided exactly what I needed. Highly recommend!

I couldn’t get the Type O mortar locally and Pro Mason Supply got it to me fast

Got their type O for my 1940's house. Works great, amazing product. Their support staff was also very helpful at editing my order. Highly recommend

Great customer service. Emails were responded to in a timely manner, answering all questions in detail. Product was easy to work with and the job finished off beautifully

Ordered masonry stain to change the color of my stone grout. Love that I don't have to re-grout in order to get the look I'm going for. Keep up the good work!

Took me a year (due to pauses in the project) but I’m finally finished! Stripped thick white paint off of my fireplace and all the scrubbing and scraping left the brick with a grey wash. I used the burgundy stain and it’s like it was never painted!

Will need help with the proper dilution level of your stone gray color

Loved how this turned out. Before and after. I used the charcoal gray and added randomly. I LOVE the way it turned out!!!

Fantastic experience. Ordering is so easy, shipping is fast, and the plaster has been easy to use.