Mortar Mixing Demonstration - Quart-Size Container :

Type O Mortar FAQ's

What does "Type O" mean?

"Type O" is a specific classification for mortar designated by the American Society for Testing and Materials (ASTM). It refers to a mortar mix with a low compressive strength (a minimum of 350 psi) and high lime content.

This low strength is a crucial feature, not a flaw. Type O mortar is intentionally designed to be softer and more flexible than the masonry units it's used with, such as historic, handmade bricks or soft natural stone.

Why is this important? In older buildings, a soft mortar acts as a sacrificial element. It absorbs movement and stress, protecting the more valuable and often irreplaceable brick or stone from cracking and spalling. It's also highly breathable, allowing moisture to escape from the wall, which is essential for the long-term health of historic structures.

Our ProMason Type O Lime Based Mortar Concentrate is specifically formulated for these applications, ensuring you have the right material for gentle and effective historic masonry restoration.

Is this the right mortar for my project?

Type O mortar is considered a "transition mortar". This is when older pure-lime mortars were being transitioned to our modern hard-cement mortars. Often a lime mortar was modified by adding a small amount of cement to make it set faster and harder than the old lime mortars. If your building was built between 1920 - 1950, there is a good chance that this mortar is appropriate for that structure.

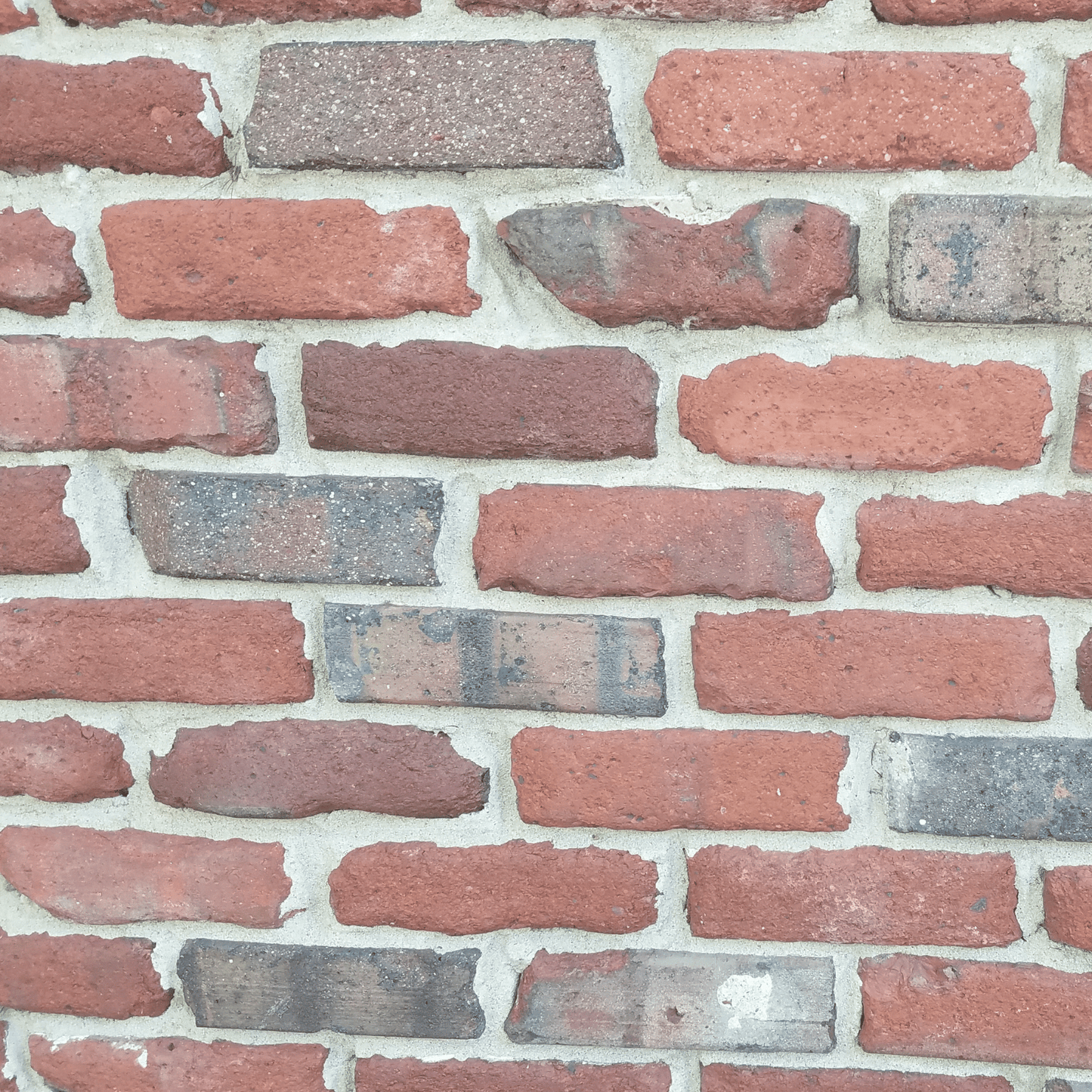

The golden rule of masonry restoration is that the repair mortar must be softer than the original masonry units. Type O mortar is designed to be soft and flexible, ensuring that it won't damage delicate, historic materials.

One way to do a simple field-test to help determine if pure lime mortar or Type O is useful is to scratch the surface of your mortar with the edge of a sharp tool. If it scratches or crumbles very easily, it's likely a pure lime mortar (not Type O). If it is harder and concrete-like (and from this approximate time period), you will likely want to use Type O.

Is Type O a lime mortar?

Type O is considered a high-lime or lime-based mortar.

Type O mortars are formulated under ASTM C270 specifications to have a high proportion of hydrated lime relative to cement. This mixture is useful for restoration work for the transition time period from the old lime mortars to modern high-strength masonry mortars.

While it is dominated by the characteristics of lime, the inclusion of a small amount of Portland cement means it is not a pure lime mortar (like our PHL mortars), which contains no cement at all.

Is this mortar for repointing only?

No, its use is not limited to repointing, although that is its primary and most popular application. The gentle strength and high breathability of Type O mortar make it suitable for several other applications involving historic masonry.

It is also an excellent choice for:

- Laying Brick and Stone: Type O is the appropriate mortar for laying or re-laying soft, historic bricks or porous natural stone. The key is to ensure the mortar's strength is compatible with the masonry units.

- Bedding and Setting: It can be used to set stone sills, lintels, and coping stones on historic structures where a soft, forgiving mortar is required.

In all these applications, the guiding principle is the same: Type O is used where a softer, breathable, lime-rich mortar is needed to protect and work in harmony with older, more delicate masonry substrates.

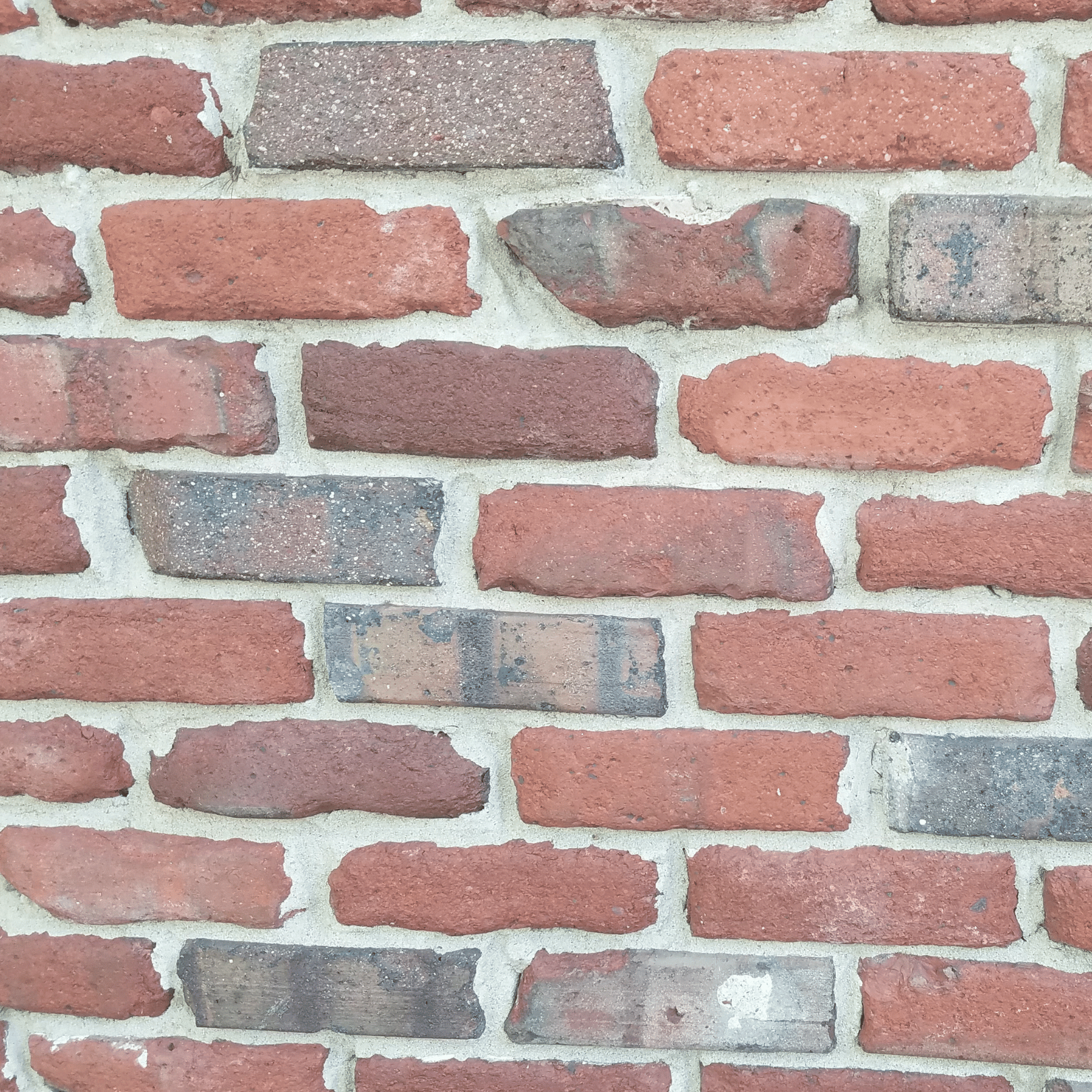

Should I clean the bricks after repointing?

Yes, a final cleaning is an important last step to achieve a professional and tidy finish. This process removes the inevitable mortar haze, smears, and splatters that occur during repointing, restoring the clean, sharp appearance of the brickwork.

For this delicate task, it is vital not to use harsh, aggressive acids (like muriatic acid), which can permanently damage both the new lime mortar and the face of historic bricks.

This is why we specifically developed Pro Mason Mortar Wash. It is a gentle masonry cleaner formulated to safely dissolve fresh mortar haze and stains without attacking the integrity of the joints or the masonry.

Following the product directions, use it with a soft-bristle brush and a low-pressure rinse to put the finishing touch on your restoration project

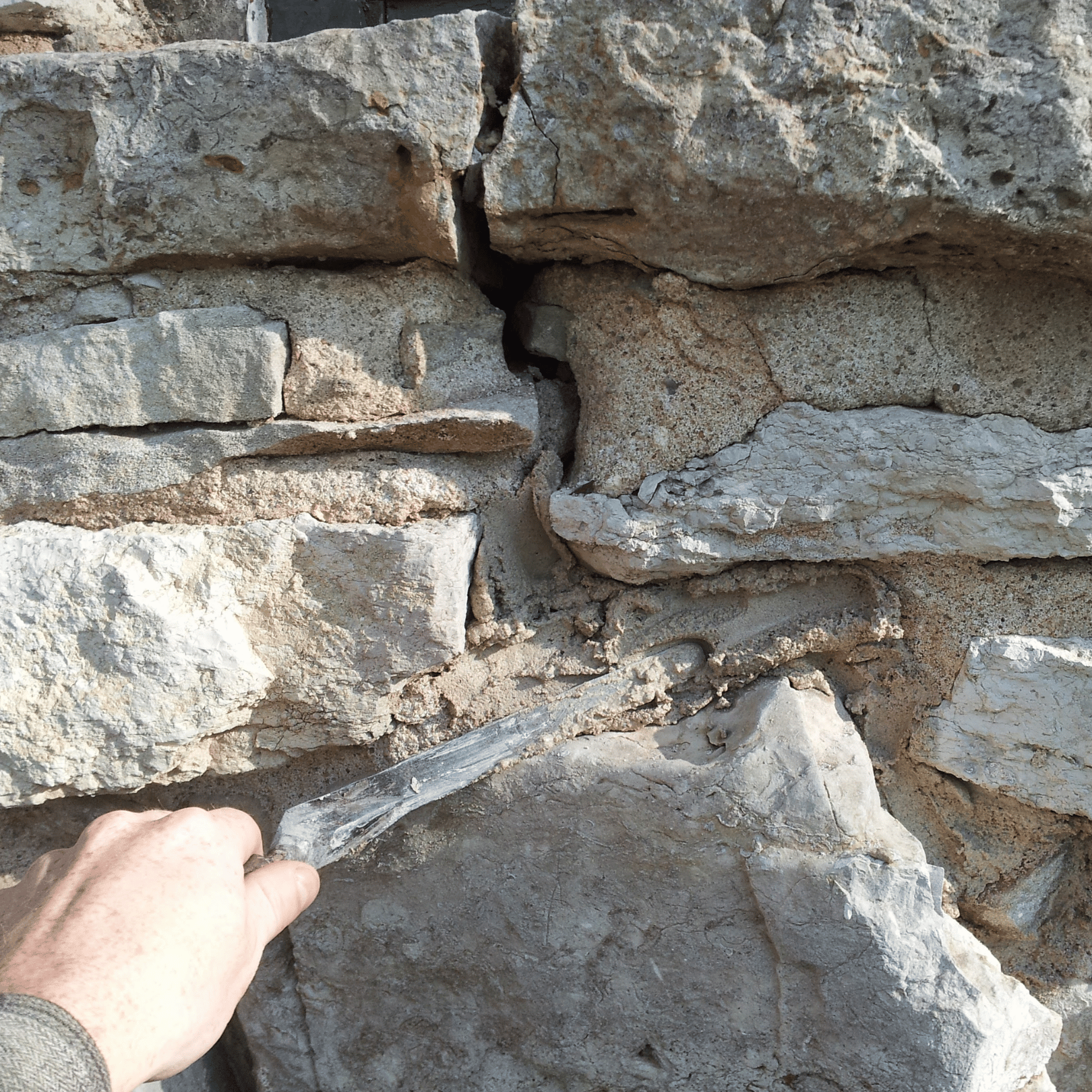

Should I first remove old mortar to a specific depth?

Yes, removing the old, deteriorated mortar to a proper and uniform depth is a key step for achieving a long-lasting repointing job.

The industry-standard guideline is to remove the old mortar to a depth of 2 to 2.5 times the width of the mortar joint.

For example, for a common 3/8" wide mortar joint, it's recommended to excavate the old mortar to a depth of at least 3/4" to 1". A plugging chisel is a useful tool for this process.

Why is this depth recommended?

This depth allows the new mortar enough surface area to create a solid mechanical bond and lock itself into place. A shallower application may not be as durable and could be more susceptible to premature failure from weather and freeze-thaw cycles.

A key consideration is to continue removing old mortar until you reach a solid, sound base, even if this is deeper than the guideline. The goal is to provide a clean, stable surface for the new mortar to adhere to. It's always best to be careful during removal not to damage the edges (arrises) of the brick or stone.

Does this mortar require special curing methods?

Yes, because Type O is a high-lime mortar, proper curing is essential for it to gain full strength. Unlike modern cements, it cures slowly and needs moisture. For the best results:

- Keep it Damp: Lightly mist the new mortar joints with water daily for at least 3 to 7 days. This prevents the mortar from drying out too quickly.

- Protect from Weather: Shield the wall from intense sun, high winds, and heavy rain, which can disrupt the slow curing process.

- Avoid Freezing: Protect from freezing for 1 week after application. Plastic sheeting can be used for light frost protection at night during this time period.

Is this mortar suitable for any size mortar joint?

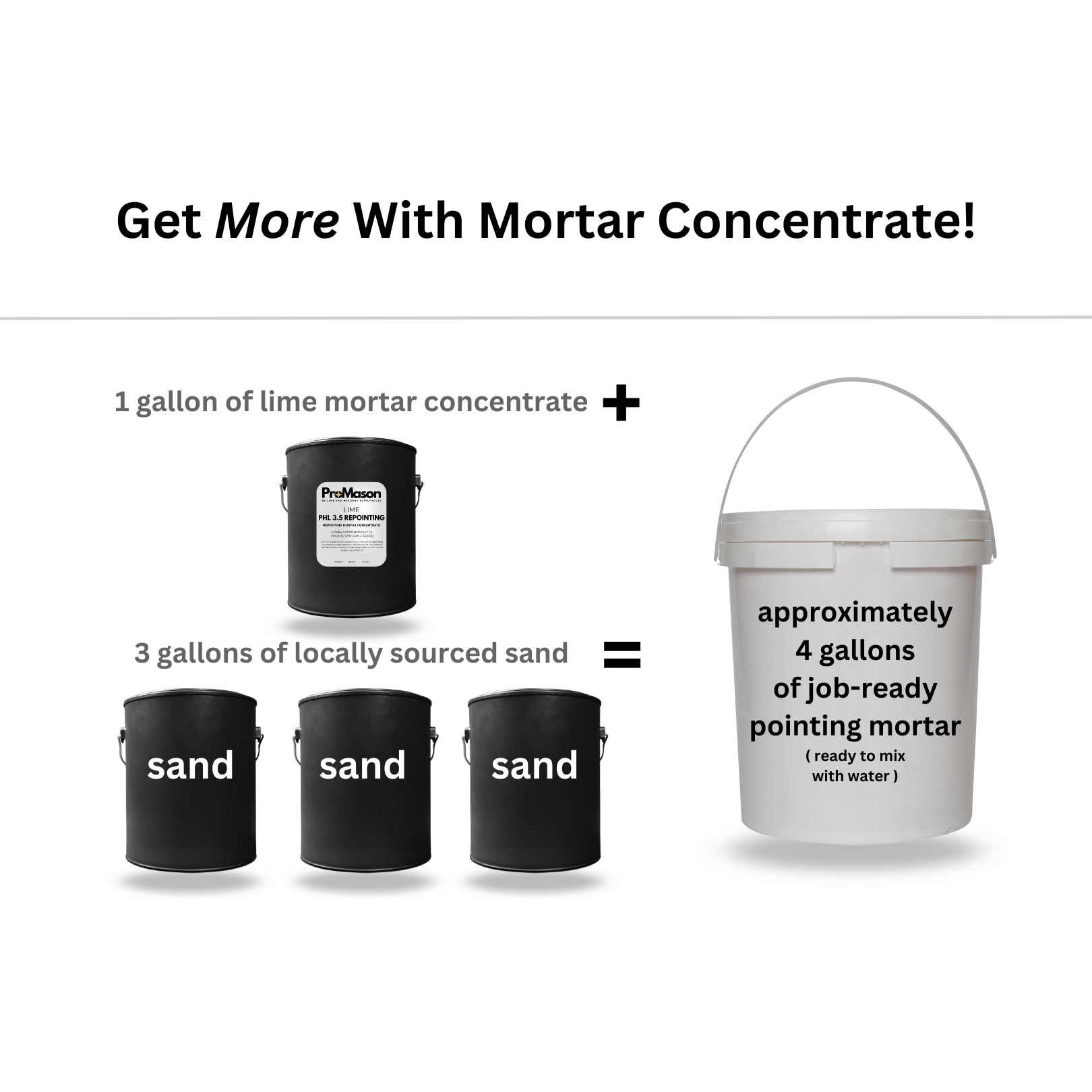

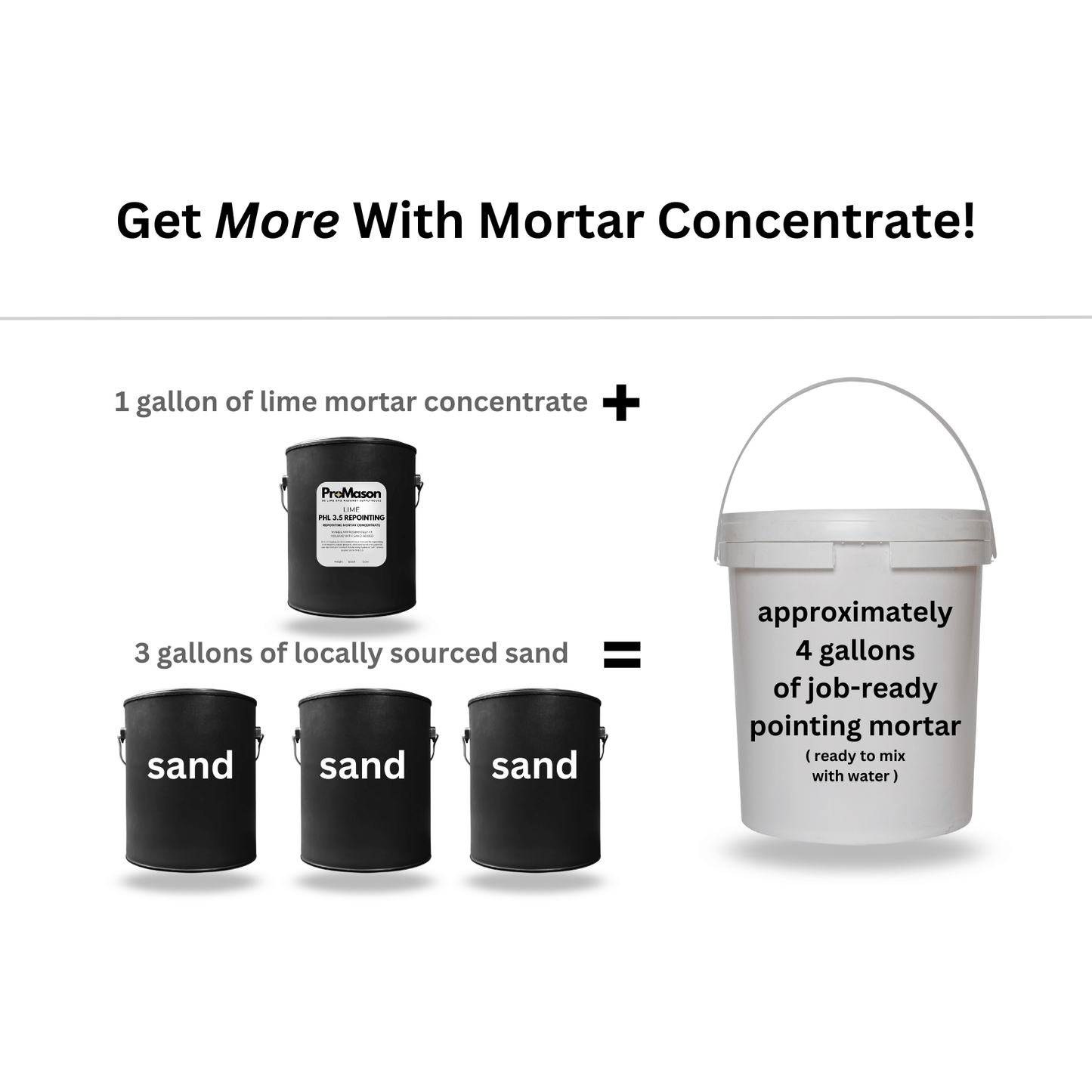

Yes, but you must match the sand you mix with our concentrate to the joint size. The general guideline is the largest sand grain should be no more than one-third the joint's width.

- For narrow joints (under 3/8"): Mix our concentrate with a fine masonry sand (such as ASTM C144) to ensure a tight, complete fill.

- For wide stone joints (over 3/4"): Mix our concentrate with a coarse, well-graded sand. This provides the necessary stability and helps control shrinkage in larger gaps.

Is this mortar for both brick and stone?

Yes, Type O mortar can be used for both brick and stone restoration projects.

Is this mortar suitable for flatwork or only walls?

No, our Type O mortar is designed exclusively for vertical wall applications and is not suitable for flatwork such as patios, walkways, or steps.

The unique characteristics that make Type O mortar perfect for historic walls—its softness, low compressive strength, and high breathability—make it the wrong choice for horizontal surfaces.

Flatwork requires a mortar with high strength and durability to withstand foot traffic, abrasion, and direct weather exposure. Type O mortar is soft and porous, and if used on the ground, it would quickly fail due to:

- Freeze-Thaw Damage: Horizontal surfaces trap water. The high porosity of Type O mortar would allow it to become saturated, and it would be destroyed when that water freezes and expands.

- Low Wear Resistance: The mortar is not designed to resist the abrasion from foot traffic and would wear away quickly.

- Salt & Chemical Attack: Deicing salts used in winter would chemically attack and rapidly deteriorate the lime-rich mortar.

For flatwork applications, you should use a much stronger, denser material specifically designed for that purpose, such as a Type N mortar. Always use Type O mortar for its intended purpose: preserving and protecting historic masonry walls.